Table-Top Conveyors Provided by Lone Star Automated

Table-Top and/or Mat-Top Chain Conveyors are typically used during the manufacturing process prior to the product being boxed, although it is being utilized more in some applications for handling cased goods.

Table-Top and/or Mat-Top Chain Conveyors are typically used during the manufacturing process prior to the product being boxed, although it is being utilized more in some applications for handling cased goods.

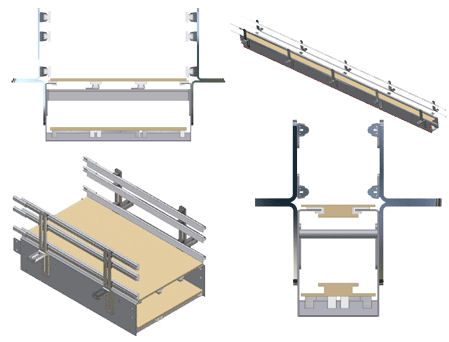

- Economical conveyor profile.

- Open and Closed Top construction.

- Heavy-duty stainless steel or painted mild steel construction.

- Bolt together design with use of vibration resistant fasteners.

- Compatible with industry standard modular plastic belts offering a continuous conveying surface.

- UHMW clip-on wearstrips and roller or serpentine slider return.

- Full array of complimentary accessories - guide rails, brackets (fixed and adjustable), product gating (powered and manual), dust covers, drip pans, supports and transfer aids.

- Complete array of modular sections - dynamic transfer section, parallel side transfers, Pressureless Singlefilers, deceleration modules, drive end, idle end and incline/decline modules.

Zero-Pressure Case Accumulation

Zero-Pressure Case Accumulation

Chain is a rollerless, zero pressure accumulation conveyor designed to transport and accumulate cartons, trays, or totes. It is designed for non-reversing travel with speeds up to 240 FPM and horizontal installation. This conveyor provides smooth and gentle positive transportation of product similar to a slider bed belt conveyor and accumulates product without line pressure build-up. The rollerless design is important in eliminating damage to package graphics and product. Roller conveyors, even with closely spaced rollers, can cause denting of cans. Transition chains are available to bridge the gap between the drive sprocket of one conveyor and the tail sprocket of the next conveyor. These chains may not be necessary on bottle handling applications, as gap-filling rollers may not damage the bottles.

Plastic Chain General Application

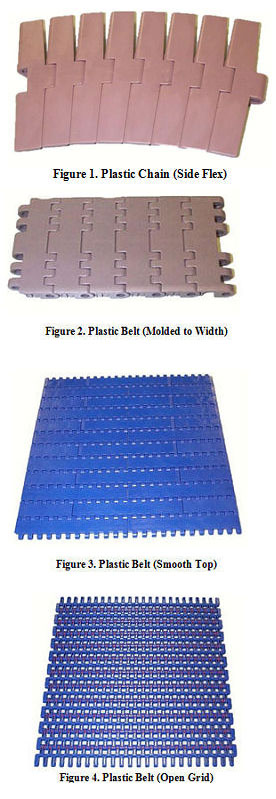

Plastic belt and chain conveyor, like traditional Belt and Chain conveyor transports product directly on a continuously moving closed loop surface. The basic conveyor consists of a drive (usually located at the discharge end), intermediate section(s), and infeed idler section. Plastic chain is used primarily for handling narrow products but can also handle wider products when multiple strands are employed. These chains are constructed similar to steel chains where individual links are connected by pins to allow the chain to flex around the end idlers and form a closed loop. A single sprocket is employed at each end of the conveyor to guide each strand of chain to and from the return side. The conveying surface consists of wings or flights that are typically molded to the top of the chain links. The flights are supported by guides or tracks, which straddle the chain in the center. Most plastic chains are side flexing which allows them to go around curved sections of conveyor. Hold down tabs are typically molded to the bottom of the chain links to prevent them from coming out of a curved track under tension (see Figure 1).

Plastic belt has a uniform cross section similar to a traditional belt and can be purchased in a wide variety of widths. Narrow belts are typically molded to width (see Figure 2) while wide belts are constructed from modular pieces that are interwoven in a brick like pattern. Pivot rods are threaded through each segment of belt to connect them together. A wide variety of conveying surfaces are available in plastic belt. Some belts have a smooth solid surface (see Figure 3) while others have an open grid (see Figure 4) to allow dirt and debris to fall through. Some have a low friction surface and some have high friction rubber pads (see Figure 5) or cleats molded into the surface for inclines, declines, and brake belt applications.

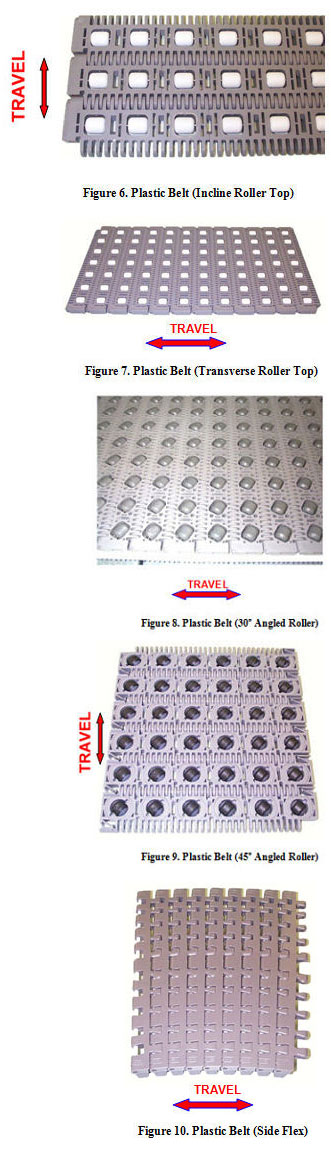

Belts with small plastic rollers imbedded or attached to the conveying surface are also available in a variety of configurations. The most common configuration employs in-line rollers (see Figure 6), which allow product to back up or accumulate on the conveyor with minimal line pressure. This is sometimes referred to as low pressure accumulation.

Another configuration employs transverse rollers (see Figure 7), which allow product to be easily transferred on or off the belt from the side of the conveyor. This type of belt is commonly used for right angle transfer applications using a pusher or puller. It can also be used for merge or divert applications that employ a swing arm or fixed deflector.

Another configuration employs transverse rollers (see Figure 7), which allow product to be easily transferred on or off the belt from the side of the conveyor. This type of belt is commonly used for right angle transfer applications using a pusher or puller. It can also be used for merge or divert applications that employ a swing arm or fixed deflector.

Belts with rollers mounted at an 30º and 45º angle (see Figures 8 and 9) to the direction of travel are a recent development in plastic belt technology. Unlike in-line and transverse rollers, which are passive or non-powered, angle rollers protrude below the bottom surface of the belt and are activated by the conveyor bed. Angle roller belts can be used for a wide variety of applications such as product justification (i.e. skew and herringbone sections), merging, diverting, sorting, and singulation.

Most plastic belts are straight running, however some side flexing belts (see Figure 10) for curved sections are available. Recent design improvements have increased the belt pull capacity for some side flexing belts allowing them to gain popularity over plastic chains.

Environmental Conditions and Restrictions

The standard operating temperature for polypropylene belts/chains is 45º to 130º F. Acetal belts/chains are available for low temperature operation down to -30º F and also for applications requiring reduced friction and high wear resistance.

Applications

Plastic belt and chain conveyors can be used in a wide variety of applications. Some of the most common applications are listed below:

- Transportation - straights and curves (belt or chain)

- Inclines/declines (belt or chain - high friction)

- Brake/meter belts (belt or chain - high friction)

- Accumulation (belt - in-line roller)

- Transfers (belt - transverse roller)

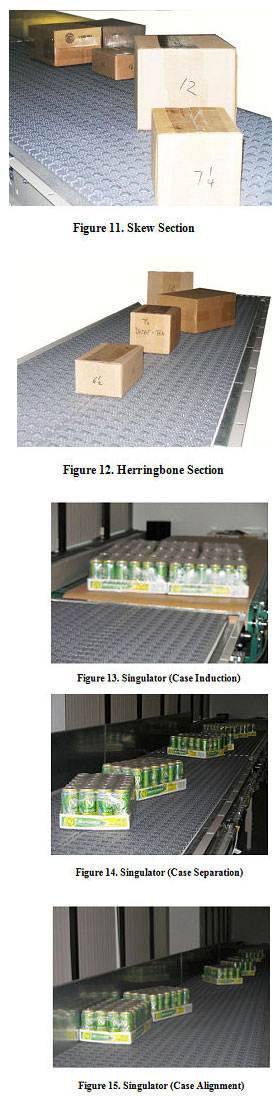

- Skews/herringbones (belt - angled roller)

(see Figures 11 and 12)

Many factors must be considered when selecting a design configuration for a plastic belt or chain conveyor. Proper selection must be based on the product or products being handled. Some important items to consider are as follows:

- Length and width requirements

- Belt or chain selection

- Drive type

- Transition requirements

Length and width requirements: When physical space is not a factor, the length of a plastic chain conveyor is generally limited by the allowable chain pull capacity or the slip-stick effect. This phenomenon, also known as chain surge, is somewhat unique to plastic belt and chain conveyors. It occurs when the initial tension of the belt or chain is insufficient to overcome the static friction with the carryway. Like a spring, the elasticity of the belt or chain allows tension to build up until it breaks free and surges forward. This in turn relaxes it causing the cycle to repeat itself. Allowing the belt or chain to surge in this manner can cause problems such as product instability, sprocket disengagement, and wear. Long, slow-moving conveyors are the most likely to experience the slip-stick effect. To avoid this problem, some plastic belt and chain manufacturers will specify a maximum allowable length for a conveyor.

Conveyor width is normally determined by the widest product to be handled, however, additional width may be needed to negotiate curved sections (refer to chapter on Powered Roller Curves for additional information). Special consideration must be given to singulators so that side by side cartons will have sufficient space to rotate freely on the angled roller belts.

Conveyor width is normally determined by the widest product to be handled, however, additional width may be needed to negotiate curved sections (refer to chapter on Powered Roller Curves for additional information). Special consideration must be given to singulators so that side by side cartons will have sufficient space to rotate freely on the angled roller belts.

Belt or chain selection: The type of plastic belt or chain best suited for a conveyor will depend on the application, product, and environment. Some of items to consider when making a selection are listed below:

- Belt or chain width

- Belt or chain strength

- Minimum sprocket size

- Frictional characteristics with product

- Operating temperature

- Straight running or side flexing

- Solid surface or open grid

- With or without rollers

A choice of materials is usually available for most plastic belts and chains. The type of material will generally affect the strength, frictional characteristics, and operating temperature. Some of the most commonly used materials for plastic belts and chains are polypropylene, polyethylene, and acetal.

- Wide merges (belt - transverse or angled roller)

- Diverters (belt - transverse or angled roller)

- Sorters (belt - angled roller)

- Singulators (belt - angled roller) (see Figures 13, 14, and 15)

Polypropylene is the most economical and has good strength characteristics, but is not recommended for cold temperature applications (below freezing). Polyethylene works well in cold temperatures, but is not as strong as polypropylene. Acetal also works well in cold temperatures, but has superior strength and lower frictional characteristics than both polyethylene and polypropylene. In addition, Acetal has a higher PV limit making it a better choice for curve applications. When selecting a material for a plastic belt or chain never use a similar material for the wearstrip or track. Like materials tend to bond together increasing friction and accelerating wear.

Drive type: An End drive should be adequate for most applications. However, if the conveyor needs to be bi-directional, a center drive should be employed.

Transition requirements: Transition plates should be adequate for case lengths greater than twice the center distance between end idlers. Transition rollers are recommended for shorter case lengths.

Accessories

Divert arms or deflectors (fixed or swing type), case stops (fixed or gate type), pushers, pullers, and bump turners are accessories commonly used with plastic belt and chain conveyors. Divert arms should be equipped with a low friction surface such as UHMW, skate wheels, or bead rail to reduce carton drag. A low friction guide rail is also recommended for skew sections with angled roller belts. Bump turners are used to rotate cases 90 degrees as they travel down the conveyor. Typically, cases are skewed to one side of the conveyor where they encounter an obstruction device that catches one corner of the case. As the conveyor continues to push forward, the back end of the case swings out and around the obstruction. Other accessories associated with plastic belt and chain conveyor are guide rails (fixed or adjustable), supports (floor or ceiling hung), and slave drives (infeed end).